HDPE PE100 & PE100-RC Pipe: Properties and Types

HDPE PE100 & PE100-RC Pipe

PE100 is the third generation of pipe grade PE.

It has an optimum balance of three key properties:

- Minimum Required Strength (MRS) – this provides long-term strength and creep resistance.

- Stress crack resistance (sometimes referred to as slow crack growth resistance).

- Rapid crack propagation resistance.

HDPE PE100 pipe is easy to install, light, flexible, corrosion-free and has a service life of up to 100 years. It can be jointed using butt fusion or electrofusion to create a leak-free pressure network for gas or water. For the trenchless applications butt fusion is most widely used because this results in a smooth exterior profile with no protrusions that might cause difficulties in pulling the pipe into the ground or host pipe.

HDPE PE100 & PE100-RC Pipe Properties

- Minimum Required Strength (MRS): 10.0 MPa (1450 psi)

- Hydrostatic Design Basis (HDB) Pressure: 1600 psi (11 MPa)

- Allowable Compressive Strength: 7.93 MPa

- Tensile Strength at Yield: 23 MPa

- Elongation at Break: >600%

- Modulus of Elasticity (50 years): 200 MPa

- Flexural Modulus: 1000 MPa

- Poisson’s Ratio: 0.45

- Thermal Expansion Co-efficient: 1.3 x 10-4 °C-1

Friction Co-efficients:

- Colebrook-White: 0.00152mm

- Hazen-Williams: 150-155

- Manning: 0.009 (water); 0.010 (sewage)

Temperature Resistance of PE pipe

The properties of HDPE PE100 pipe are determined at standard temperatures of 20°C or 23°C. These properties can be significantly affected by temperature, so at higher temperature the properties, including MRS, decrease. At higher temperatures it may be necessary to apply reduction factors to MRS, and consequently MOP. Some Codes and Standards define the reduction factors that must be applied; AWWA C901 and C906 for example. Otherwise there are standard reduction factors that can be applied in design. ISO13761:2017 defines reduction factors to be applied to MOP at higher temperatures. These are shown below.

Pressure reduction factors at operating temperatures. PE100 & PE100-RC

|

||||||

| 20°C |

25°C |

30°C |

35°C |

40°C |

45°C |

50°C |

| 1.00 | 0.92 | 0.85 | 0.79 | 0.73 | 0.67 | 0.63* |

* ISO12201-1:2024 Annex A states 0.62 for the reduction factor at 50°C

In the USA the Plastics Pipe Institute Handbook of Polyethylene Pipe Table A.2 includes the following reduction factors. The correlation with the ISO factors is clear. ISO13761:1996 defines reduction factors to be applied to MOP at higher temperatures. These are shown below.

| Temperature °F (°C) | 73 (32) | 80 (27) | 90 (32) | 100 (38) |

| Pressure Reduction Factor | 1.00 | 0.94 | 0.86 | 0.78 |

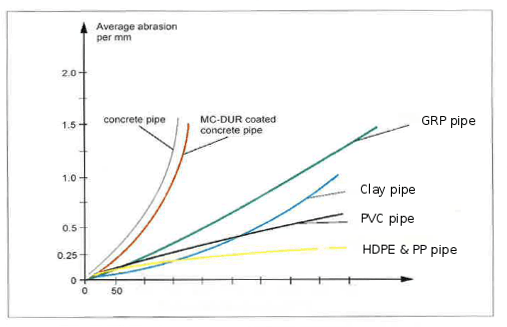

Abrasion Resistance

This is a consideration in wastewater rising/force mains in which there are solids transported with the water and pump operation sequences can result in solids rubbing along the pipe invert. PE100 & PE100-RC has the best abrasion resistance of the commonly used pressure pipe materials. This is illustrated in the Figure below.

The magnitude of wear depends on the angle of impingement and the type of material being eroded. At close to 90 degree impingement angles (impact abrasion), the erosive wear rate is highest in brittle materials and lowest in ductile materials. In ductile materials, the repeated impinging particles plastically deform the surface to generate wear debris. With brittle materials, the impingement causes particles of material to be fractured off as wear debris. Brittle materials are less wear resistant than ductile materials in an impact erosion condition. At low angles of impingement (abrasive erosion), the reverse is the case. Harder materials better resist the gouging or ploughing action of abrasive particle flow.

There is an approximate relationship between hardness and the ultimate strength of the material. The amount of abrasive wear decreases as the strength/hardness of the piping material increases. To resist abrasion, the piping system must be harder than the material being conveyed. The wear rates of various piping materials are often similar, so long as their hardness is greater than the slurry so selecting a pipe material considerably harder than the conveyed material offers no wear advantage and typically costs more. Conversely when the mineral is harder than the pipe, there is a very sudden and steep rise in the abrasive wear rate.

There are distinct types of wear experienced in a typical piping system. The straight sections most commonly experience abrasive erosion. Size transitions and directional changes experience both abrasive erosion and impact abrasion and should be designed with this in mind.

Surge & Fatigue Loading

Design process for surge & fatigue loading of HDPE PE100 pipe

HDPE PE100 Pipe Types

In addition to conventional HDPE PE100 pipe there are several variants that have been developed for specific applications.

PE100-RC

RC indicates resistance to cracking. PE100-RC is a resin that has an increased stress crack resistance while maintaining the same MRS and rapid crack propagation resistance as conventional PE100. It is intended for use in more severe conditions and is especially suitable for trenchless methods. In Europe approximately 25% of PE100 usage in trenchless applications, both new installation and rehabilitation, is PE100-RC.

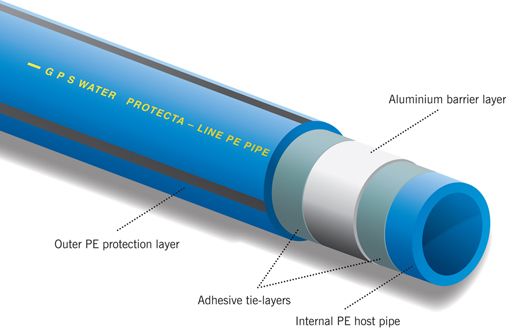

Barrier PE Pipe

Certain gases and liquids can permeate through PE. Therefore when HDPE PE100 pipe is laid in contaminated ground and the fluid in the pipe must be protected from contamination, for example when potable water is carried, then a barrier pipe is necessary. Barrier pipe is co-extruded with a barrier layer sandwiched between layers of PE100. The barrier layer is most commonly an aluminium foil but may also be a special polymer such as EVOH.

Image courtesy: GPS PE Pipe Systems

PE100 barrier pipes are made by several PE manufacturers. Examples are:

- Radius Systems: Puriton

- Egeplast GmbH: SLA

- GPS PE Pipe Systems: Protecta-Line

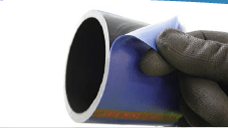

Coated PE Pipe

Coated HDPE PE100 pipe has a co-extruded harder outer layer, usually of polypropylene, to protect the PE100 itself in installation conditions that are more severe. It is especially well suited to trenchless techniques such as directional drilling and pipe bursting where there may be a risk of damage to the pipe during installation. In certain coated HDPE PE100 pipes, such as ProFuse, the outer layer is peelable to enable electrofusion couplings to be fused directly to the PE. This peelable layer has the additional benefit of keeping the PE surface clean for electrofusion.

Image courtesy: RADIUS SYSTEMS

Coated PE100 pipes are made by several manufacturers. Examples are:

- Radius Systems: ProFuse

- Egeplast GmbH: SLM

- Pipelife: Robust Pipe

Other Co-extruded PE Pipe

Co-extrusion of PE100 enables several additional pipe variants to be manufactured, often with several layers each with a different function. These include internal coatings, internal and external coatings, and conducting layers or strips for leak monitoring or pipe detection. Pipes with detection layers or strips have some application in trenchless installation because methods such as directional drilling do not permit warning marker tapes to be buried above the pipe.

Several manufacturers have particular multi-layer HDPE PE100 pipes and can provide further information.

USEFUL LINKS

Related keywords : polyethylene pipe, pe pipe, rc pipe, pe100 pipe dimensions, tensile strength of pipe, modulus of elasticity of hdpe pipe, properties of hdpe pipe, define flexural modulus, profuse pipe, yield strength of polyethylene, protecta line compression fittings, 100 pipes, compressive strength of pvc pipe, flexural modulus definition, polyethylene modulus of elasticity, properties of pipe, pe properties, protecta line barrier pipe, modulus of elasticity of pvc pipe, modulus of elasticity of polyethylene, hdpe pipe thermal expansion, yield strength of pvc pipe, hdpe compressive strength, hdpe yield strength, pipe properties, polyethylene poisson ratio, hydrostatic design basis, abrasion resistant plastic pipe, tensile strength of hdpe pipe, pipe material properties, pipe strength, hdpe thermal expansion, types of poly pipe, hdpe pipe material, hdpe pipe properties, pe material properties, hdpe modulus of elasticity, modulus of elasticity of hdpe, thermal expansion of hdpe