Pipe Reaming

PIPE REAMING - TECHNIQUE

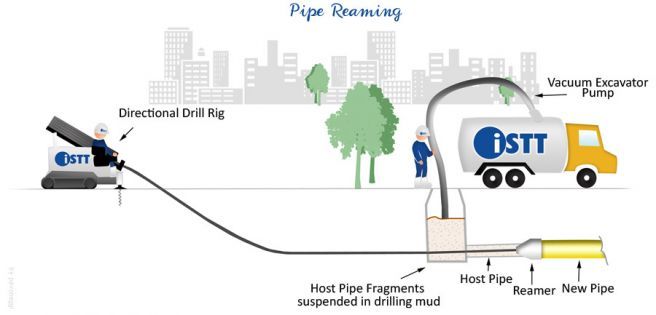

Pipe reaming, also known as pipe eating, is a trenchless pipe replacement technique that removes the host pipe while at the same time installing a new replacement pipe.

Pipe reaming is used for pressure pipes whereas pipe eating is a technique based on microtunnelling and is used for gravity sewers and therefore not used with PE100 pipe. Pipe reaming can be used to replace a number of existing pipe materials and is particularly well suited for replacing and upsizing pipes in stiff soils and rock where pipe bursting may not be an option. Pipe reaming is limited to non-metallic pipeline replacement. The new pipe installed is a PE100 or PE100-RC pipe suitable for installation using directional drilling equipment. There is also a variation of this method for gravity sewers adapted from microtunnelling.

Image courtesy: INTERNATIONAL SOCIETY FOR TRENCHLESS TECHNOLOGY

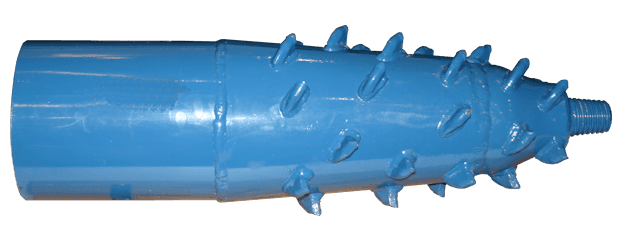

Pipe reamer attached to PE100 water pipe. Note drilling fluid flowing from ports in reamer for transport of pipe fragment cuttings.

Image courtesy: NOWAK PIPE REAMING.

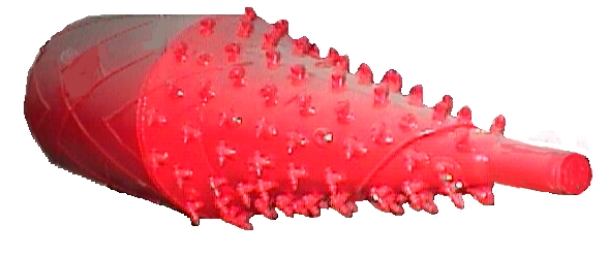

Pipe reamer entering old pipe. Note alignment for uniform contact with old pipe.

Image courtesy: NOWAK PIPE REAMING.

PIPE REAMING - PE100 APPLICATIONS

- Water mains.

- Gas mains.

- Pressure sewers.

PIPE REAMING - INSTALLATION PROCEDURE

For pipe reaming a horizontal directional drilling (HDD) machine with minor modification is used to insert a drill string through the host pipe to be replaced. This is then connected to a special reamer (see Figures below) and the new PE100 pipe string is attached to the reamer via a swivel and towing head. The directional drill back-reams through the host pipe enlarging the hole and the old pipe is ground up and replaced by the new PE100 pipe. The fragments of the old pipe along with other cuttings are suspended in drilling fluid and pushed ahead of the reamer through the existing pipe to a recovery pit or manhole where they are extracted, separated and disposed of. The new replacement PE100 pipe attached to the reaming tool is pulled in as the reamer advances.

Directional drilling contractors or utility contractors who use an HDD rig can add specially modified reamers of various types for different pipe materials and ground conditions. Otherwise the procedure is as conventional Horizontal Directional Drilling.

PIPE REAMING - EQUIPMENT

The pipe reaming method uses standard Horizontal Directional Drilling equipment and ancillaries. A modified backreaming tool is the only special tool required for the technique. This may be modified by the manufacturer or by the contractor to meet the specific project needs. It is important that the selected reamer be in good condition with sharp bits and/or cutting edges. Reamers are in general multi-purpose as shown below, however very hard vitrified clay pipe (VCP), concrete, concrete encased pipe, or upsizing in rock, will require special reamers. A variety of reamers for various piping and conditions are available from the various HDD tool suppliers.

Image courtesy: Plastics Pipe Institute

Image courtesy: Nowak Pipe Reaming

PIPE REAMING - PRACTICALITIES

Upon entry into the host pipe the reamer may wobble and not engage well with the cut face of the pipe because the roller cones or teeth are not in uniform contact with the face of the pipe. Once cut into the pipe the reamer should become stable. This condition can be avoided by configuring the gradient at the entrance point to provide, as nearly as possible, uniform contact of the reamer with the cut face of the pipe. This will prevent uneven fracturing which can continue the difficulty for a longer distance, and prevent possible damage to the reaming tool. Once stabilized, the reamer progresses at a rate of approx. 20metres per hour.

Pipe materials: pipe reaming is suitable for non-metallic pipe only.

Upsizing is possible but may be limited in rock and hard clay soils.

Soil Types and their effects

- Hard rock.

- Soft rock.

- Clay.

- Silt.

- Sand.

- Fine gravel.

- Coarse gravel.

- Boulders.

Diameter, Pressure and Length Range

Diameter range 200-900mm. Length up to 300m.

Pressure is a function of the SDR of the installed PE100 pipe.

PIPE REAMING - EXCAVATIONS

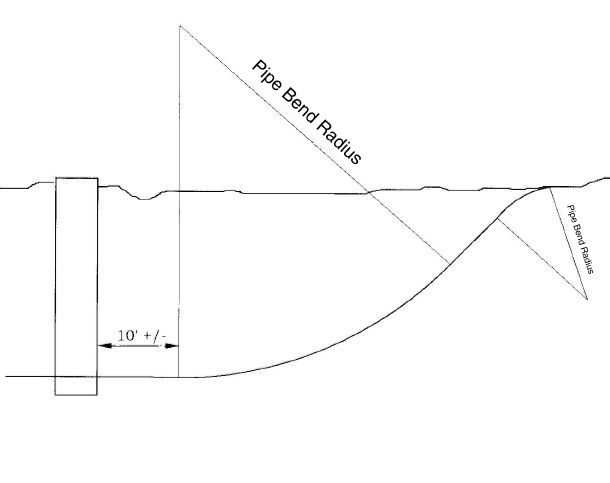

The excavation size at both the insertion and extraction ends of the operation must include a length of approx. 3 metres to allow the PE100 pipe to enter into or emerge from the bore without bending beyond the recommended allowances. This is shown below. Otherwise excavation sizes are as for conventional Horizontal Directional Drilling. Minimum pipe bend radius depends on the diameter and SDR of the PE100 pipe. Reference should be made to pipe manufacturer’s recommendations and to IGEM/TD/3

Image courtesy: Nowak Pipe Reaming

See also Excavations, pit sizes, Space and Access

PIPE REAMING - DESIGN, SPECIFICATION & PLANNING

Design

- Fluid/hydraulic design for capacity of new pipeline to determine diameter needed.

- Select SDR based on operating pressure

- Check tension load capacity during pull-in

Specification

- Specify maximum allowable tensile load during pull-in based on pipe manufacturer’s recommendations.

- Specify surface protection to PE100 pipe if necessary depending on soil type and upsizing. Consider pipe with external protective PE coating.

- Specify end fittings and service connection details.

Planning

- Pre-CCTV recorded survey of the existing pipe is recommended to identify and obstruction to the reamer.

- Pit locations. Pits may need to be long to accommodate the reamer and allow straight entry into the host pipe.

- Straight runs of pipe only – no bends

- Proximity of other utilities and services. This method can cause some ground movement if upsizing.

- Containment and disposal of asbestos cement pipe fragments in accordance with local regulations.

PIPE REAMING - HEALTH, SAFETY & ENVIRONMENT

This method applies tension to the PE100 pipe during installation. The tensile load on the pipe during installation must be calculated to establish whether it exceeds the maximum allowable load. Pipe manufacturers can advise on the allowable loads. If the calculation shows that the maximum permissible load may be exceeded then it may be necessary to increase the capacity of the PE100 pipe by increasing its thickness. This will require a check of ID and OD to ensure that flow capacity and external clearances are still adequate.

COMMON/SECONDARY MODULES

- Pipe assembly & handling

- Installation Manual

- Isolation

- Host pipe cleaning & inspection

- End fittings

- Testing & inspection

- Piecing up

- Excavations & pit sizes

Related keywords : what is reaming, pipe reaming, pipe reamers, pipe reaming tool, how to ream a pipe, select trenchless pipelines, hdpe gravity sewer pipe, reaming a pipe, encasing of pipes by concrete, horizontal directional drilling bend radius, no dig equipment, entry reamer, what is a pipe reamer used for, plastic pipe reamer, reamer specification, reamer pipe, pipe reamer tool, ream pipe

PIPE BURSTING / SPLITTING - TECHNIQUE Pipe bursting and pipe splitting are trenchless methods used to replace existing pipelines with PE100 or PE100-RC in the same alignment without physically...